Last Tuesday Stephen Mouzon arrived in Atlanta to give two lectures describing his philosophies, and how they might help Decatur accomplish it's projected community goals more effectively. I was lucky enough to be invited to a dinner party in honor of Stephen the night before the lectures. The guest list of six included the City Planner, the Assistant City Manager, the City Commissioner and Decatur's most prominent journalist. Scott Doyon of 'PlaceMakers' worked with the City to contract Stephen to come to Decatur and speak, and the evening gathering was hosted by Scott and his wife Robin at their Historic home in the City of Decatur.

It was a wonderful opportunity for everyone to engage Stephen personally, and, within a casual, wine induced atmosphere, throw ideas out on the table with great seriousness, sarcasm and laughter. I was especially taken with the man's passion, and how easily his beliefs flowed, seasoned by that rooted, Southern, sing-song delivery that will always do one of two things when authentic: endear you, or make you think we're crazy. In one moment, Stephen would yank his coke bottle glasses off his eyes, and jerk his face in with a hard look past your pupils, . . . and then relax, returning spectacles to their place as if nothing ever happened. I was so intrigued by this process, and the resonant ideas spilling forth that I could hardly take my eyes off him.

The lack of a pen and paper, and the improper alternative to note taking on my phone was really the only frustrating bit of the evening. One self deprecating comment I remembered Stephen remarking was, "You don't write books because of what you know — you write books because of what you want to learn." That seemed to be the true spirit of the man, and as far as nut shelling his philosophy on Architecture and the environment, I won't do it justice and whole heartedly recommend reading the book, 'The Original Green."

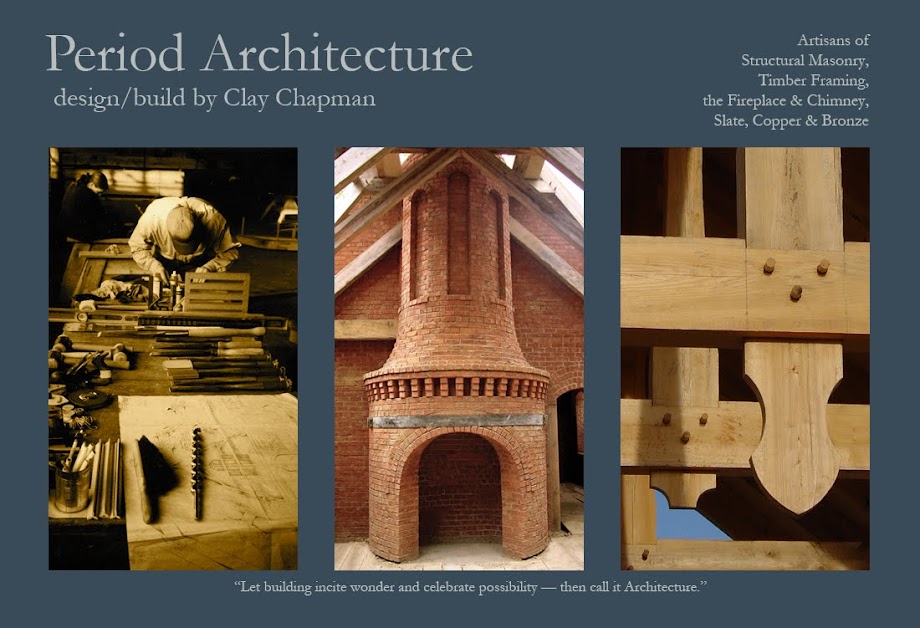

The next morning I met with Scott and Stephen for Coffee at Kavarna in Oakhurst where we continued our waxing on about favorite concepts, and I was encouraged by the discourse in a very pertinent and palpable way. I've yet to make public a new building model we are currently developing. Sometime in January, we should be breaking ground on a prototype house with a structural masonry shell that will be based on a $100.00 per foot price point. Further details will be given later, but my point in bringing this up now is that Stephen was quite receptive to the idea at a time when a voice like his could have thrown serious doubt on the plan had he felt otherwise. So we move forward.