In August 2010, I was contacted by Bryan Light of the the Brick Industry Association (BIA) and asked to participate in a discussion with the EPA about regulating fireplace emissions. While working in concert with the Masonry Contractors Association of America (MCAA), the BIA organized a dialogue between select members of the brick industry and EPA representative Gill Wood on August 18th, 2:00pm Eastern. A dozen or so Contractors, Architects and Masons from all over the country contributed to this discussion. Final comments were emailed to EPA representative Lucinda P. Powers by 12:00, September the 11th.

The concern by those of us effected in the brick industry by this potential regulation is as follows:

1. Emission testing would be expensive and would fall to the builder's or masonry company's expense.

2. That on-site-built masonry fireplaces are already inhibited by a number of obstacles. Required testing would add to that burden and make it even more difficult to bring on-site-built fireplaces into production.

The general protest against regulation by brick industry representatives revolved around job loss in the market place. It is my whole hearted opinion that this is not a good argument because jobs are simply not more important than the environment; we might go a step further and ask what is ever more important than the environment. The more important question to ask in this case would be, "is this truly a relevant contributor to the global pollution problem when there are so many blatantly ignorant and obviously disastrous activities damaging the air we breath?

It makes sense that

any pre-manufactured wood burning heating system should undergo rigorous testing to insure that particulates admitted are kept at a minimum. But true

Masonry Fireplaces* are built so infrequently that the resources required to create a program for regulation would be an inordinate mis use of tax dollars. The real dilemma in masonry fireplace regulation deals with the fact that no two are alike, as opposed to pre-manufactured systems which are, of necessity, homogenized to only a few different sizes. This is the thing that would make testing so expensive and prohibitive — each test would have to be customized to the specific parameters of every

Masonry Fireplace* constructed.

As a great proponent of the masonry built fireplace, there is a particularly pertinent and personal observation I should mention: Last year, in my own home I only built two fires. The fireplace, is not just about fire, but an important architectural element to the aesthetic of a home's interior. This said, people in general enjoy a significant and inherent connection with "fire," and even though I only took full advantage of my fireplace twice last year, it was still important to me to be able to do so.

With some regret, much of what I've mentioned so far in this introduction was not included in my final comments to the EPA, but they are more familiar with the general dialogue than the readers here might be and much of what has been mentioned in the introduction above would have been redundant to include in the statement.

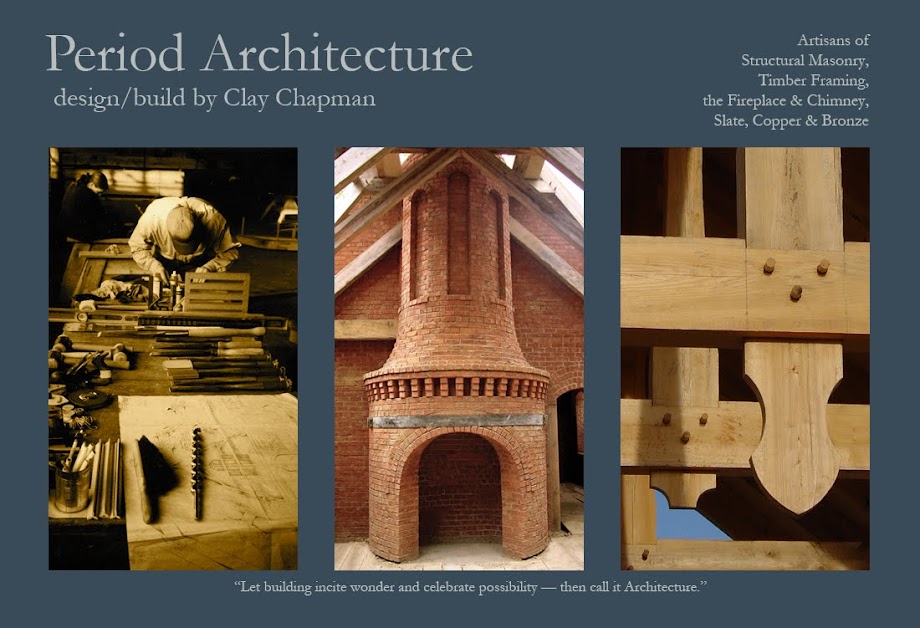

The following is my email to the EPA concerning the fireplace emissions issue — I included images of

Masonry Fireplaces* I have built intermingled with the text as a ready reference to the matter at hand :

For the sake of the discussion, I will identify the three types of fireplaces most commonly associated with the term "fireplace" :

1. Pre-manufacture Fireplace Insert : Made of steel, sheet metal and ceramic, this light weight, inexpensive, production oriented, fireplace is by far the most common in building today. It arrives on site as a single boxed unit and does not require masonry.

2. Pre- manufactured Fireplace Kit : Isokern made by Earthcore is a good example of this fireplace type.

The sturdy kit is assembled on site and is generally augmented by applied masonry though not necessarily. Utilizes cast iron throat dampers and/or chimney top dampers.

3. Masonry Fireplace : Refers to the traditional fireplace type that is built on site one brick or stone at a time; this is the least commonly built fireplace today.

Because of the definitive parameter "on-site-built," the fireplace type introduced above as "1. Pre-manufactured Fireplace Insert" is not pertinent to the discussion.

The question deals with the particulate emissions of on-site-built fireplaces and how these emissions might be tested, regulated and minimized.

Jobs created in the market place by fireplace production are not more important than the environment.

I am a professional designer, mason and timber framer. I personally build architecturally sensitive Masonry Fireplaces and chimneys and have only built 6 in the last three years.

Because I am always interested in new construction, I visit construction sites frequently, and have not seen another Masonry Fireplace being built in the Atlanta area in that time. The only thing I have seen, in terms of on-site-built fireplaces, is the Pre-manufactured Fireplace Kit which is cost comparable to a true Masonry Fireplace, but does not require the same degree of skill and is generally faster to construct.

As an exercise, I think it would be an interesting challenge to try and find a Masonry Fireplace being built now or in the last year.

The only legitimate statistical indicators for on-site-built fireplaces would be damper sales because, whether wood burning or gas, each on-site-built fireplace is constructed with a single damper. The caveat to this damper figure is that while cast iron throat dampers represent the vast majority, chimney top dampers are also implemented.

It would not be an impossible leap to determine the rough number of individual damper sales through damper dealers, both throat and chimney top types within the last year — but the real challenge would be determining what portion of those sales represent Pre-manufactured Fireplace Kits and what portion represents Masonry Fireplaces. All this to say, based on reasonable observation, I believe Masonry Fireplace production to be fractional to that of Pre-manufactured Fireplace Kits.

Economically this would make sense because laypeople are not able to differentiate between the two types of fireplaces and there is a cost advantage to the Pre-manufactured Fireplace Kit because it is faster and less complicated to construct.

If this is the case, the moderate amount of particulate produced by the few Masonry Fireplaces being constructed today does not justify the effort it would take to monitor them. In addition, this is a dying art — its very difficult to believe that the annual number of Masonry Fireplaces being built is remotely significant to the particulate issue at hand. As a kind of "endangered species," I would ask you to take the Masonry Fireplace's continued existence very seriously.

The reality of the matter is revealed in how readily that metaphor resonates — it's obvious that in our snap together, get it done yesterday, conventional construction mentality that the "artisan-craftsman" is running on life support.

Masonry Fireplace design is still incredibly important to the world of architecture and nothing should be done to discourage it.

End.

While so many modern distractions seem pitted to divide us further and further from our natural history, a fire at the hearth is still one of the few tangible reminders of who we are and where we come from. If the environment is to be truly protected, we have to be able to identify with it. The alternative is to suppose we are separate from, and above, the very thing that allows us to exist. And while much of the green movement is extreme, and even erroneous, it is only a response to the opposite extreme which, in my opinion, is much less forgivable.