Gray Fox on path between camp and the Betts Lodge.

Wednesday, August 10, 2011

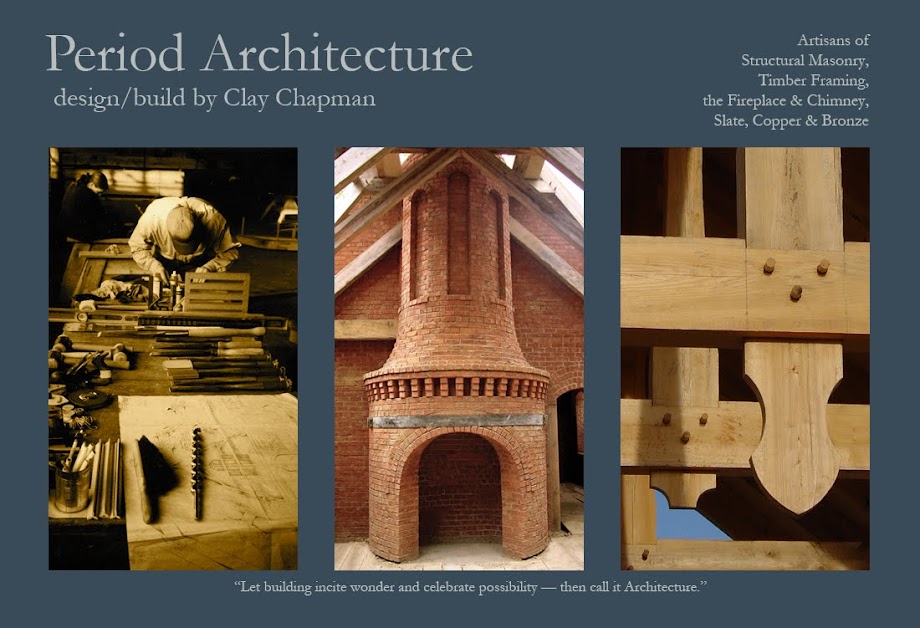

Completion of the Dickey Betts Fireplace and Chimney Project

Tuesday, August 9, 2011

Monday, August 8, 2011

Friday, August 5, 2011

Thursday, August 4, 2011

Betts Fireplace and Chimney Project, Day 22

Fitting the final pieces of a difficult puzzle. A dry stack arch requires a great deal of patience and focus. When building one of this size, you're constantly searching for the perfect fit. A degree of mental stamina is necessary — many considerations take place before each stone is found.

Mason Alejandro taking measurements for in-stepping stone work.

Completed archway of wood vault.

Here I am with fellow Mason Alejandro Hernandez. Alejandro is an extremely competent Mason and trusted friend.

Mason Alejandro taking measurements for in-stepping stone work.

Completed archway of wood vault.

Here I am with fellow Mason Alejandro Hernandez. Alejandro is an extremely competent Mason and trusted friend.

Wednesday, August 3, 2011

Betts Fireplace and Chimney Project, Day 21

Stone work progressing.

Interesting brick deterioration phenomena I came across in local town. The mortars manufactured 100 years or so ago were generally inferior to that of today, and typically these low grade mortars decay quicker than the brick of the same era. In this case however, the mortar is in tact, and the the bricks are all but gone in places. There were small holes created by some kind of mite like insect, and I thought this may have played a part in the attrition, but as it turns out these are most likely incidental. The insects, being opportunist, probably burrowed into the faulty brick as they would the ground. I contacted Bryan Light of the Brick Industry of America's Southeast Region and asked for his take on the matter:

Clay,

The photos depict the results of freeze thaw action on soft brick. Several things can cause this to take place.

1) Reuse of brick that were lightly fired and never intended for use on exterior walls.

2) Tuck-pointing older brickwork with a mortar that is too strong. The new mortar bonds well with the soft units, however mortar (as does concrete) shrinks a bit as it cures. As the mortar shrinks it pulls the faces of the brick ever so slightly, but enough for water to enter the units very easily. The increased amount of water now in the brick freezes/expands and spalls the bricks face off. This continues to occur every successive winter from then on.

3) Coating the exterior wythe of brickwork, allowing that coating to deteriorate and trap moisture, rather than sheeting the water off the wall. Freezing does it’s work. It is sort of the same thing as allowing paint to scale or peel on wood siding. Soon the wood rots.

4) Water at times enters the wall at a higher location than where the failure is occurring. Is there a parapet that is in bad shape above these photos?

Whatever has happened, something has allowed excess water penetration into the wall. This is a water related problem. No way to stop it. A colorless coating might slow it down.

Bryan Light

Technical Services Manager

Brick Industry Association SE Region

P.O. Box 1139

Conyers, GA 30012-1139

O) (770) 760-0728

F) (770)760-7810

C) (770) 846-0728

blight@bia.org

Tuesday, August 2, 2011

Monday, August 1, 2011

Betts Fireplace and Chimney Project, Day 19

Hearth floor is laid with solid clay brick — no images to show for this day of production.

Subscribe to:

Comments (Atom)